|

Getting your Trinity Audio player ready...

|

Coal mining is a multifaceted process that encompasses diverse methods for extracting a crucial fossil fuel that has powered human civilizations for centuries.

Coal resources play a significant role in meeting global energy demands, with vast reserves contributing to the production of approximately 8.3 billion metric tons of coal in 2022.

Coal mining remains a critical component of the global energy landscape, yielding approximately 8.3 billion metric tons of coal in 2022, according to the International Energy Agency (IEA). Historically, this abundant fossil fuel powered the Industrial Revolution, fueling factories, locomotives, and power plants worldwide. Yet, the modern coal industry faces unprecedented challenges, from economic pressures and environmental considerations to technological shifts in the broader energy sector.

In this article, we examine coal mining’s historical evolution, delve into its core methods and technologies, explore current industry trends, and highlight future-facing innovations. By balancing historical context with contemporary developments, we can better understand coal’s role in meeting global energy needs and the hurdles it must overcome to stay viable in an era increasingly defined by climate targets and sustainability.

What is Coal Mining?

Coal mining is the process of extracting coal, a fossil fuel, from the Earth, which can be done through either surface (open-pit) or underground mining methods.What is Coal Mining?

Coal mining is the process of extracting coal, a fossil fuel, from the Earth, which can be done through either surface (open-pit) or underground mining methods.

History of Coal Mining

Ancient Use of Outcropping Coal

From archaeological digs revealing Bronze Age funeral pyres in Wales to the writings of Aristotle and Theophrastus, coal has served humankind for millennia. In Roman Britain, coal was burned before 400 CE, leaving telltale cinders at ruins and along the Roman wall.

Initially, easily accessible surface outcroppings allowed for rudimentary extraction. But by the Middle Ages, such reserves were largely depleted, forcing miners to innovate. Shaft mining eventually supplanted surface prospecting, paving the way for more extensive underground operations. This transition underscores how scarcity of exposed seams spurred technological progress.

Evolution of Coal Mining Methods

Coal mining methods have undergone significant transformations over the years, driven by advances in technology, changes in market demand, and growing concerns about environmental sustainability. The evolution of coal mining methods has been shaped by the need to improve efficiency, reduce costs, and minimize environmental impacts.

In the early days of coal mining, extraction was labor-intensive. Miners would dig shallow pits and tunnels to access coal deposits, using simple tools like pickaxes, shovels, and baskets. This manual approach was not only physically demanding but also limited in scope and efficiency.

The advent of the Industrial Revolution marked a turning point for the coal industry. Mechanization and industrialization brought about significant changes, with the introduction of steam engines and conveyor belts. These innovations allowed for larger, more complex mining operations, boosting productivity and transforming the coal industry into a cornerstone of industrial growth.

By the mid-20th century, room-and-pillar mining had become a widely adopted method. This technique involved extracting coal from a series of small rooms, leaving behind pillars of coal to support the roof. Room-and-pillar mining improved both efficiency and safety, enabling more extensive underground operations.

The latter half of the 20th century saw the rise of longwall mining, which quickly became the dominant method for underground coal extraction. Longwall mining involves extracting coal from a long, continuous face, supported by hydraulic jacks and conveyor belts. This method allows for high recovery rates and has become a cornerstone of large-scale coal production.

A crucial part of the coal extraction process is the coal preparation plant, which washes coal to meet quality standards before further use. Many coals, whether extracted via surface or underground mining, require this washing process to ensure they meet the necessary quality for various applications.

Today, coal mining methods continue to evolve, focusing on improving efficiency, reducing costs, and minimizing environmental impacts. Modern techniques leverage advanced technologies such as robotics, automation, and data analytics to optimize extraction processes and reduce waste. These innovations are crucial for the coal industry as it navigates the challenges of sustainability and market dynamics.

Coal Deposits in the World

Coal deposits are found across the globe, with significant concentrations in regions that have historically played a pivotal role in the development of the coal industry. These deposits are categorized based on their geological formation, age, and carbon content, which influence their suitability for various applications.

Major Coal Deposits

Coal deposits are found across the globe, with significant concentrations in regions that have historically played a pivotal role in the development of the coal industry. These deposits are categorized based on their geological formation, age, and carbon content, which influence their suitability for various applications.

China (approximately 162 billion tonnes):

As the world’s largest coal producer and consumer, China boasts extensive coal deposits, particularly in the northern provinces such as Shanxi, Shaanxi, and Inner Mongolia. These regions are rich in bituminous and sub-bituminous coal, which are crucial for China’s energy and industrial sectors.

United States (approximately 250 billion tonnes):

The U.S. is home to vast coal reserves, with significant deposits located in the Appalachian region, the Illinois Basin, and the Powder River Basin in Wyoming and Montana. The diversity of coal types, including bituminous, sub-bituminous, and lignite, supports various energy and industrial needs.

India (approximately 101 billion tonnes):

With rapidly growing energy demands, India relies heavily on its coal deposits, primarily found in the eastern and central parts of the country. Jharkhand, Chhattisgarh, and Odisha are notable for their substantial coal seams, which are vital for electricity generation and industrial activities.

Australia (approximately 149 billion tonnes):

Known for its high-quality coal, Australia is a leading exporter, particularly to Asian markets. The country has significant coal reserves in New South Wales and Queensland, producing both thermal coal for power generation and metallurgical coal for steel production.

Russia (approximately 177 billion tonnes):

Russia possesses some of the largest coal reserves globally, with major deposits in Siberia and the Far East. The Kuznetsk Basin in southwestern Siberia is particularly notable for its high-grade bituminous coal.

Botswana (approximately 212 billion tonnes):

Botswana holds significant coal deposits, especially in the eastern and southern regions of the country. The Mmamabula coalfields and other deposits are increasingly important for regional energy needs and export potential.

South Africa (approximately 30 billion tonnes):

As Africa’s leading coal producer, South Africa’s coal deposits are primarily located in the northeastern regions, including the Highveld, Witbank, and Ermelo coalfields. These deposits are crucial for domestic power generation and export.

Geological Formation and Types

Coal deposits are formed from the remains of ancient plant material that accumulated in swampy environments millions of years ago. Over time, heat and pressure transformed this organic matter into coal. The main types of coal—anthracite, bituminous, sub-bituminous, and lignite—vary in carbon content and energy output, influencing their use in different industries.

Global Importance

Coal deposits are a vital part of the global energy landscape, supporting electricity generation, industrial processes, and economic development. While the coal industry faces challenges from environmental concerns and the rise of alternative energy sources, coal remains a key resource for many countries, especially those with abundant deposits and growing energy needs.

Understanding the distribution and characteristics of coal deposits worldwide is essential for developing strategic approaches to energy production, economic growth, and environmental management.

Coal Mining Methods

Modern coal mining methods can be broadly subdivided into surface and underground techniques. Factors such as seam depth, overburden volume, and local regulations heavily influence whether a site can be profitably and responsibly mined.

Surface Mining

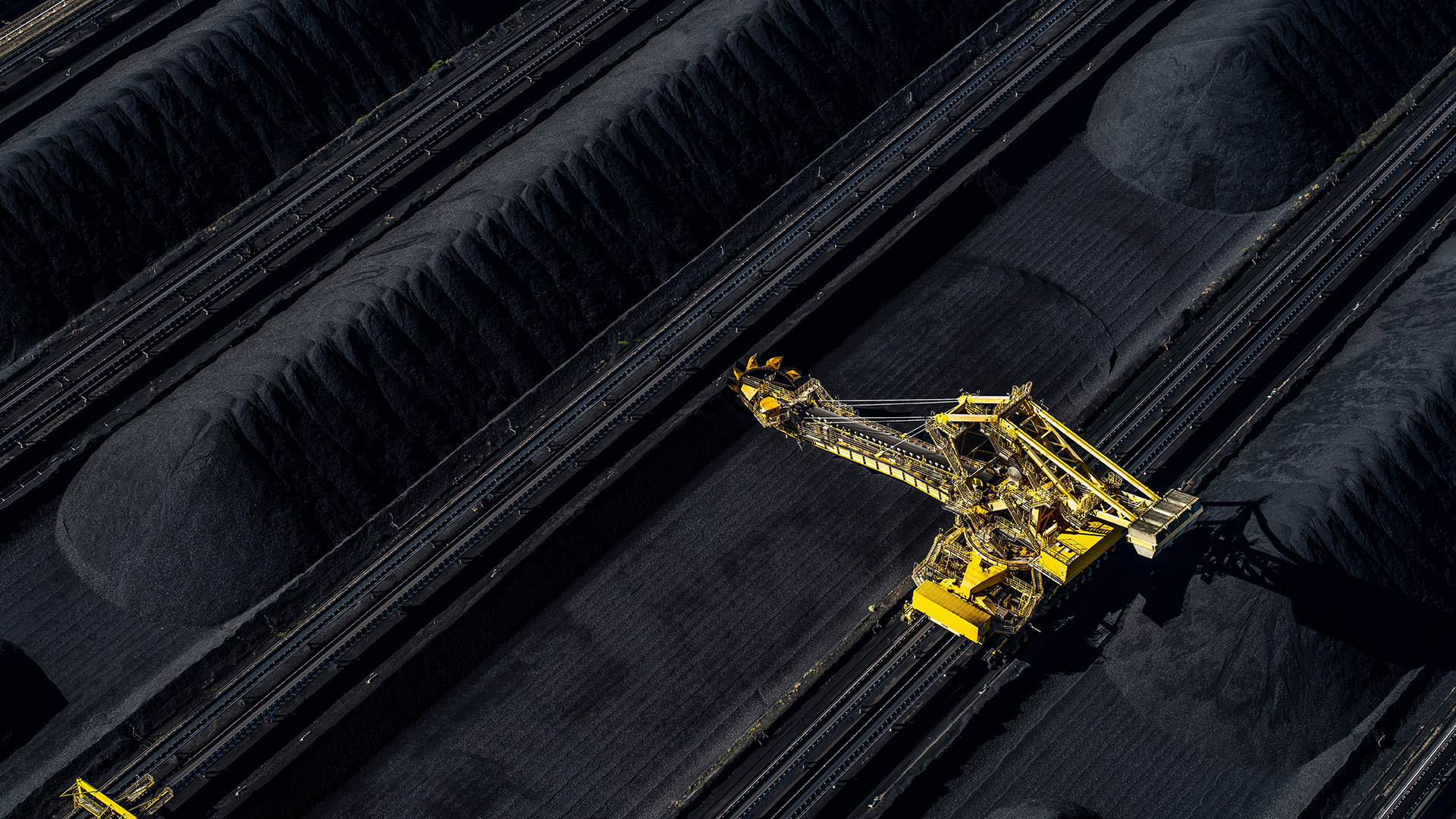

Surface mines typically occur where coal seams lie within about 200 feet of the surface. According to recent data, surface operations produced roughly half of all coal globally in 2022, underscoring its ongoing relevance.

Surface mining techniques often involve removing overburden to expose coal seams, allowing for the extraction of coal from near-surface deposits.

Contour Strip Mining is often used in mountainous or hilly terrain, where overburden is peeled away following the seam’s outcrop.

Area Strip Mining instead applies to flatter regions, proceeding in successive cuts or trenches.

Open-Pit Mining uses a series of benches and can accommodate thicker or steeper seams

Auger Mining recovers leftover coal by boring horizontally into previously exposed seams.

Advantages and Considerations

Surface mining boasts lower overhead compared to underground operations, leveraging large machinery and straightforward access. Methods like mountaintop coal mining, however, can lead to significant ecological concerns, including permanent “valley fills” that alter waterways and habitats. This specific method of surface mining involves the removal of entire mountaintops to access coal seams below, creating drastic changes in the landscape and ecosystems.

Critically, profitability in surface mining hinges on the stripping ratio, or the amount of overburden removed relative to coal extracted. The higher this ratio, the less economical the operation. Comprehensive reclamation programs—encompassing land recontouring, topsoil replacement, and revegetation—have become standard in many jurisdictions, reflecting growing societal and regulatory demands.

Mountaintop Removal

Mountaintop removal is a specialized form of surface mining designed to access coal deposits located in steep or rugged terrain. This method involves the removal of the mountain’s summit to expose coal seams beneath. The process begins with the clearing of vegetation and topsoil, followed by the use of explosives to break apart the rock layers. Heavy machinery then removes the overburden, the rock and soil overlaying the coal seam, to expose the coal for extraction.

While mountaintop removal can be an efficient way to access coal deposits that are otherwise difficult to reach, it is highly controversial due to its significant environmental impacts. The removal of the mountain top can lead to deforestation, soil erosion, and the destruction of local ecosystems. Waterways can become polluted with debris and chemicals, affecting both wildlife and human communities downstream. The visual impact of the altered landscape is also a concern, as it can permanently change the natural scenery.

Despite these environmental concerns, mountaintop removal remains prevalent in regions like Appalachia, where the coal industry argues that it is necessary for economic viability. The method allows for the extraction of coal that would be too costly to mine using traditional surface mining techniques. However, environmental groups and local communities continue to advocate for stricter regulations and the development of alternative mining methods that minimize ecological damage.

Underground Mining

When coal reserves lie deeper than 200 feet, underground coal mine methods become more practical. Deep underground mining is often employed when coal reserves lie deeper than 200 feet, utilizing advanced techniques to access these deeper deposits. This approach accounts for an estimated four billion metric tons of annual coal output worldwide.

Room-and-Pillar Mining supports the roof with coal pillars, enabling partial extraction rates of 50–70%.

Longwall Mining uses mechanized shearing and self-advancing hydraulic supports, often topping daily outputs of 20,000 tons in a single face.

Shortwall Mining follows a similar principle on a smaller scale, and Thick-Seam Mining subdivides thicker deposits into workable slices.

Economic and Safety Factors

Underground mining generally involves higher expenditures due to ventilation systems, specialized equipment, and robust safety measures. Ventilation alone can circulate 7 tons of air per ton of coal in high-gas seams. Moreover, real-time gas detection, dust monitoring, and rigorous training have become indispensable to protect workers from explosions, cave-ins, and respiratory hazards.

Coal Mining Techniques

Continuous Mining

Historically, extracting coal entailed separate crews for undercutting, drilling, and loading. The advent of the Joy Ripper in 1948 heralded a new era, integrating these steps into a single continuous miner.

This innovation dramatically reduced labor requirements while boosting productivity. Today, continuous miners dominate room-and-pillar operations in underground coalfields worldwide, streamlining what was once a labor-intensive process.

Longwall Mining

Longwall mining’s historical roots trace back centuries, but modern variants feature advanced automation:

The Loebbe System (1940s): Introduced a coal plow and continuous conveyor, fundamentally shifting the rate of extraction.

Power-Advanced Supports: Mobile hydraulic shields move with the shearer, ensuring worker safety and maintaining roof stability.

With potential recovery rates exceeding 75%, longwall mining is a cornerstone of large-scale underground coal production, particularly in Europe, North America, and Australia.

Coal Mining Process

The coal mining process is a complex series of stages that transform raw coal deposits into usable energy resources. This process involves several key steps, each critical to ensuring the efficient and safe extraction, processing, and transportation of coal.

Extraction

The extraction phase is the first step in the coal mining process. It involves removing coal from the earth using various techniques, depending on the depth and location of the coal seam. Surface mining methods, such as strip mining and open-pit mining, are used when coal seams are located near the surface. These methods involve removing the overburden to expose the coal seams. In contrast, underground mining techniques, such as room-and-pillar and longwall mining, are employed for deeper coal deposits. These methods require the construction of tunnels and shafts to access the coal seams.

Coal Industry Trends

Global Production and Types

World coal output is dominated by bituminous coal (~65%), while lignite (~25%) and anthracite (<10%) split the remainder. Each variety is suited to different applications, from electricity generation to metallurgical processes.

Several nations dominate production:

China: Consumes over half of global coal, driven by its vast manufacturing sector.

India: Rapidly expanding demand for power underpins ongoing production growth.

United States: Though a top producer, U.S. coal output has declined since its early 2000s peak.

Indonesia: Leading global exporter of thermal coal, focusing on Asian markets.

The State of Coal in the U.S.

The coal industry in the United States remains a significant player in the country’s energy landscape, despite facing numerous challenges. Historically, coal has been a cornerstone of U.S. energy production, powering industries and homes across the nation. However, the industry is currently navigating a period of transition, influenced by economic, environmental, and regulatory factors.

In recent years, the U.S. coal industry has experienced a decline in production and consumption. This trend is largely driven by the increasing availability and affordability of natural gas, as well as the growing adoption of renewable energy sources. Environmental regulations aimed at reducing carbon emissions have also played a role, leading to the retirement of older coal-fired power plants and a shift towards cleaner energy alternatives.

Despite these challenges, coal remains an important energy source in certain regions of the U.S., particularly in areas where alternative energy sources are less accessible or economically viable. The industry continues to invest in technologies that improve the efficiency and environmental performance of coal-fired power plants. Additionally, coal exports to international markets, particularly in Asia, provide a vital revenue stream for U.S. coal producers.

The future of the U.S. coal industry will depend on its ability to adapt to changing market dynamics and regulatory landscapes. Innovations in clean coal technologies, such as carbon capture and storage (CCS), and efforts to improve the sustainability of mining operations will be crucial for the industry’s long-term viability.

Impact of Natural Gas on the Coal Industry

The advent of hydraulic fracturing and horizontal drilling revolutionized natural gas supply, slashing gas prices:

Power Sector Shifts: Gas-fired plants often offer cheaper, lower-emission electricity, displacing coal capacity.

Coal Plant Retirements: Older facilities increasingly opt for retirement or conversion to gas.

Forward Outlook: As gas remains plentiful, coal faces stiff competition, especially in developed economies pursuing cleaner energy.

Coal Industry and Economy

The coal industry plays a significant role in the global economy, providing a vital source of energy for power generation, industrial processes, and transportation. The industry is also a major employer, supporting millions of jobs worldwide.

Coal production is a global enterprise, with over 50 regions involved in its mining operations. The largest producers include China, the United States, India, and Australia, each contributing significantly to the global supply. The international coal trade is robust, with coal being transported by sea, rail, and road to meet the diverse demands of different regions.

Coal prices are influenced by a range of factors, including global demand, supply chain disruptions, and environmental regulations. Market trends are increasingly shifting towards cleaner, more sustainable energy sources, which is impacting the coal industry. As countries adopt stricter environmental policies and invest in renewable energy, the demand for coal is experiencing fluctuations.

Despite these challenges, the coal industry remains a significant employer. Millions of people around the world work in coal mining jobs, from extraction to transportation and processing. However, employment numbers are declining in some regions due to automation, mechanization, and shifts in market demand. This transition poses economic challenges for communities that have long relied on coal mining for their livelihoods.

The economic impact of coal mining on local communities is substantial. Mining operations generate revenue, create jobs, and stimulate economic growth. However, the industry also faces challenges related to environmental sustainability and social responsibility. Balancing economic benefits with environmental and social considerations is crucial for the long-term viability of the coal industry.

Environmental Impacts

Environmental Regulation and Coal Miners

Decades of intensive coal extraction left behind deforested landscapes, polluted water, and greenhouse gases. Over time, legislation like the Clean Air Act of 1970 in the U.S. limited sulfur emissions, spurring mining of low-sulfur coal and adoption of abatement technologies.

Mountaintop Removal faced scrutiny due to its drastic alteration of mountainous ecosystems. Consequently, many nations enforce stricter reclamation mandates, often requiring operators to restore or remediate mined land immediately upon reaching final pit boundaries.

Clean Coal Technologies

“Clean coal” encompasses a suite of innovations—scrubbers, low-NOx burners, carbon capture and storage (CCS), and more—aimed at reducing coal’s environmental footprint. While these solutions enhance plant efficiency and curb emissions, they also entail higher upfront costs and complex regulatory hurdles.

Safety and Health

Safety Improvements in Modern Mining

From the lethal dangers of past centuries, coal mining has evolved into a sector prioritizing risk reduction:

Gas Monitoring & Ventilation: Constant measurement of methane and carbon monoxide, alongside advanced ventilation layouts, lowers explosion hazards.

Equipment Advancements: Remote-controlled continuous miners and self-contained self-rescuers (SCSRs) provide emergency oxygen supplies.

Statistical Gains: Between 1990 and 2004, injuries halved and fatalities dropped by two-thirds, showcasing real progress.

Methane Capture: Some mines harness methane to generate power, reducing both explosion risk and greenhouse gas emissions.

Nonetheless, threats persist. Rock falls, fires, and health issues like black lung disease remain areas of concern, driving ongoing research and policy reforms.

Coal Miners and Working Conditions

Coal miners play a critical role in the coal industry, working in challenging conditions to extract coal from the earth. Working conditions in the coal industry can be hazardous, with miners facing risks related to safety, health, and environmental sustainability.

Safety is a paramount concern in coal mining. Miners are exposed to risks such as explosions, rock falls, and machinery accidents. Modern mining operations have implemented rigorous safety measures, including advanced gas monitoring systems, robust ventilation layouts, and emergency response protocols. These measures are designed to protect miners and reduce the likelihood of accidents.

Health issues are also a significant concern for coal miners. Prolonged exposure to coal dust can lead to respiratory diseases such as black lung disease and chronic obstructive pulmonary disease (COPD). Additionally, miners may face an increased risk of cancer and other occupational health hazards. Efforts to improve health outcomes include regular medical screenings, protective equipment, and dust control measures.

Working conditions for coal miners are demanding. Miners often work long hours in physically strenuous environments, facing extreme temperatures and confined spaces. The physical and mental toll of mining work underscores the importance of supportive workplace practices and comprehensive health and safety programs.

Labor laws play a crucial role in protecting the rights and interests of coal miners. Regulations ensure safe working conditions, fair labor practices, and adequate compensation. Advocacy for miners’ rights continues to be essential, as the industry evolves and new challenges emerge.

By addressing safety, health, and working conditions, the coal industry can better support its workforce and ensure the well-being of coal miners.

Electric Power and Coal

Role of Coal in Electric Power Generation

Despite a decline in its share of the global energy mix, coal continues to play a crucial role in electric power generation, accounting for approximately 27% of worldwide electricity production. This enduring significance is attributed to several factors:

In the United States, environmental mandates and the availability of low-cost natural gas have accelerated the retirement of older coal-fired power stations. However, coal still contributes significantly to the national power grid, particularly in regions where alternative energy sources are less accessible or economically viable. The transition towards cleaner energy is ongoing, with many coal plants investing in emissions-reducing technologies to comply with stringent environmental regulations.

In contrast, many nations in Asia and Africa view coal as a cornerstone for baseload power generation. These regions often cite coal’s cost-effectiveness, abundance, and local resource availability as key drivers for its continued use. Countries such as China and India invest heavily in modernizing their coal-fired power plants to improve efficiency and reduce emissions, ensuring that coal remains a vital component of their energy strategies.

Technological advancements are pivotal in reducing the environmental impact of coal-fired power generation. Ultra-supercritical boilers, Integrated Gasification Combined Cycle (IGCC) technology, and carbon capture and storage (CCS) systems are at the forefront of efforts to shrink coal’s carbon footprint. These innovations enhance plant efficiency and significantly cut emissions, making coal a more sustainable option in the face of global climate change challenges.

As the world increasingly shifts towards renewable energy sources, the coal industry faces mounting pressure to adapt. The transition involves integrating cleaner technologies and improving operational efficiencies to compete with the growing adoption of wind, solar, and natural gas. Despite these challenges, coal remains a reliable and essential energy source, particularly in regions where renewables cannot yet consistently meet energy demands.

While the global energy landscape is evolving, coal continues to play a vital role in power generation. Its future will likely depend on the industry’s ability to innovate and align with global sustainability goals, ensuring that coal-fired power remains a viable and responsible energy source for years to come.

Electric Power and Safety

Coal-fired power plants are a major consumer of coal in the United States, playing a crucial role in the country’s energy production. These plants convert coal into electricity through a process that involves burning coal to produce steam, which then drives turbines to generate electricity. Despite the rise of natural gas and renewable energy sources, coal-fired power plants continue to contribute significantly to the national power grid.

Safety is a paramount concern in the coal industry, particularly in coal-fired power plants. These facilities must adhere to stringent safety regulations to protect workers and the environment. Measures include regular maintenance of equipment, rigorous training programs for employees, and the implementation of advanced monitoring systems to detect potential hazards. Additionally, coal-fired power plants are equipped with technologies to reduce emissions and minimize environmental impacts, such as scrubbers and low-NOx burners.

The coal industry is also focused on improving the safety of mining operations. Modern mining techniques and equipment have significantly reduced the risks associated with coal extraction. Continuous monitoring of air quality, the use of protective gear, and emergency response protocols are standard practices to ensure the safety of coal miners. Efforts to address health issues, such as black lung disease, through regular medical screenings and dust control measures, are also critical components of the industry’s safety initiatives.

In conclusion, while the coal industry faces numerous challenges, it remains a vital part of the U.S. energy landscape. Ongoing efforts to enhance safety, improve environmental performance, and adapt to changing market conditions will be essential for the industry’s future success.

Conclusion

Future of the Coal Industry

Coal mining stands at a crossroads, facing convergent pressures from tightening carbon goals, public opposition, and competing energy technologies. Yet in many countries, coal remains indispensable for reliable, large-scale power, steelmaking, and industrial applications.

Market Pressures will likely intensify, as renewables and natural gas expand their footprints. Regulatory Landscape changes, including stricter limits on air and water pollutants, reinforce the need for cleaner coal solutions. Additionally, Sustainability Imperatives—from robust reclamation practices to carbon capture—signal that any long-term viability for coal hinges on demonstrating responsibility and innovation.

In navigating these complexities, coal producers must invest in advanced extraction technologies, community engagement, and environmental safeguards. Whether through improved reclamation, cleaner combustion techniques, or diversification into alternative energies, the industry’s resilience depends on aligning with a world increasingly determined to reduce climate impacts. By embracing continuous innovation and responsible stewardship, coal can maintain relevance—even as the global energy transition accelerates.

Frequently Asked Questions About Coal Mining

How bad is coal mining for the environment?

Coal mining has significant environmental impacts, including deforestation, habitat destruction, and pollution of air and water. Techniques like mountaintop removal can drastically alter landscapes and ecosystems. Efforts are being made to mitigate these effects through reclamation and cleaner technologies.

Do coal miners get paid a lot?

Coal miners’ salaries vary depending on location, experience, and the specific mining job. While some positions can offer competitive wages, others may not be as lucrative. Overall, coal mining jobs can provide a decent income, but they often come with challenging working conditions.

What is the main purpose of coal mining?

The primary purpose of coal mining is to extract coal, a vital fossil fuel used for electricity generation, steel production, and various industrial processes. Coal remains a key energy source in many parts of the world, despite growing competition from renewable energy and natural gas.

Is coal mining still a thing?

Yes, coal mining is still active in many parts of the world. While its role in energy production is declining in some regions due to environmental concerns and the rise of alternative energy sources, coal remains a significant part of the global energy mix, especially in emerging markets.

What Is Killing the US Coal Industry?

Several factors are contributing to the decline of the US coal industry, including competition from cheaper natural gas, the rise of renewable energy sources, and stringent environmental regulations. These factors have led to the closure of coal plants and a decrease in demand for coal.

What is the U.S. Energy Information Administration?

The U.S. Energy Information Administration (EIA) is a government agency responsible for collecting and analyzing energy data. It provides independent statistics and analysis on various energy sources, including coal, helping to inform policy decisions and market strategies.

How is coal transported?

Coal is typically transported by rail, barge, or truck, and sometimes through pipelines in the form of slurry. Transportation is a critical component of the coal supply chain, influencing costs and accessibility.

What are the different types of coal?

Coal can be classified into several types based on carbon content and energy output: anthracite, bituminous, sub-bituminous, and lignite. Each type has different uses, ranging from electricity generation to industrial applications.

How do coal mining methods differ?

Coal mining methods are broadly categorized into surface mining and underground mining. Surface mining is used when coal seams are near the surface, while underground mining is employed for deeper deposits. Each method has its own set of techniques and equipment.